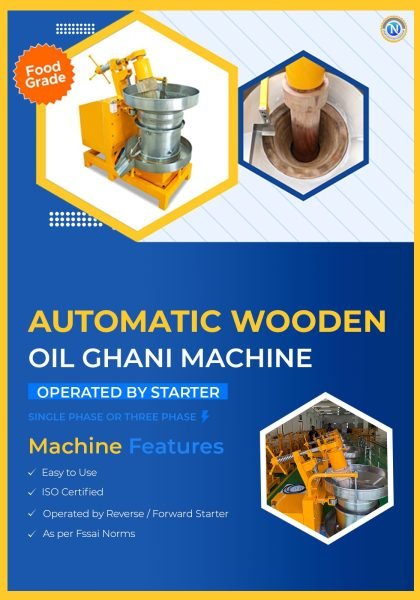

OIL GHANI MACHINE

- “Introduction”

| SEEDS : | OILS (%) |

|---|---|

| GROUNDNUT OIL | 46-50% (Depends on oil seed quality) |

| SESAME OIL | 46-50% (Depends on oil seed quality) |

| COCONUT OIL | 65-68% (Depends on oil seed quality) |

| ALMOND OIL | 48-50% (Depends on oil seed quality) |

| WALNUT OIL | 65-68% (Depends on oil seed quality) |

| CASHEW OIL | 45-55% (Depends on oil seed quality) |

| SAFFLOWER OIL | 40-48% (Depends on oil seed quality) |

| SUNFLOWER OIL | 35-40% (Depends on oil seed quality) |

| MUSTARD OIL | 28-35% (Depends on oil seed quality) |

| FLAXSEED OIL | 28-35% (Depends on oil seed quality) |

| NIGER OIL | 28-35% (Depends on oil seed quality) |

- Technical Specification:

– Capacity: 12 To 20 Kg. Per Hour

– Machine Total Weight: 580 to 590 kg

– Power Consumption: 2-3Unit/hr. Up to 30% Power saving on smart machine

– Machine Dimension/Size: H4.5XL4XW4.5FEET

– Oil Percentage/Yield: 48 to 85% (Depends on oil seed Quality & Oil making process)

– Batch Time: 35 to 40 Min per Batch

– Tank and Oil Collection Tray Material: Jindal stainless steel 304. Food Grade

– Machine & Gear Box Bearings: SKF/FAG

– Tension Springs: Steel Spring, Food Grade

– Scrapper: SS304 with 45-degree moveable

– Gear Box: 2nos: reducing & Inline Helical Gear

– Motor: 1&3Phase – 3HP Make- Siemens-Innomotics

– Tool Box: Tapariya Spanner Set, with Floor Pad

– Nuts and Bolts: Unbroko/EBERO High Tension

– Water Tank: 35 Liter HDP water tank with DC motor with jaquar Fittings and pipes

– Paint: Powder Quoting (Asian / Burger)

– Control Panel (With Rittal Enclosures)

– VFD Controller: 5 HP Danfoss – Denmark

– PLC: WYCON/Omron

– Machine Speed Controller Witches

– Temperature & RPM meter with temperature sensor and Selec Meters

– Batch time monitor meter (selec/Multispan)

– Reverse Switch/ Pot

– Cable & wiring: Polycab/FINOLEX

– MCB inside Panel: Siemens main incomer – L&T

– Machine Design and Developed as Per Fssai Norms

Smart Wooden Oil Ghani Machine with VFD Panel, RPM, Oil, Batch time monitor Mete

– Capacity: 12 To 25 Kg. Per Hour

– Machine Total Weight: 580 to 590 kg

– Power Consumption: 2-3Unit/hr. Up to 30% Power saving on smart machine

– Machine Dimension/Size: H4.5XL4XW4.5FEET

– Oil Percentage/Yield: 48 to 85% (Depends on oil seed Quality & Oil making process)

– Batch Time: 35 to 40 Min per Batch

– Tank and Oil Collection Tray Material: Jindal stainless steel 304. Food Grade

– Machine & Gear Box Bearings: SKF/FAG

– Tension Springs: Steel Spring, Food Grade

– Scrapper: SS304 with 45-degree moveable

– Gear Box: 2nos: reducing & Inline Helical Gear

– Motor: 3Phase – 5HP Make- Siemens-Innomotics

– Tool Box: Tapariya Spanner Set, with Floor Pad

– Nuts and Bolts: Unbroko/EBERO High Tension

– Water Tank: 35 Liter HDP water tank with DC motor with jaquar Fittings and pipes

– Paint: Powder Quoting (Asian / Burger)

– Control Panel (With Rittal Enclosures)

– VFD Controller: 5 HP Danfoss – Denmark

– PLC: WYCON/Omron

– Machine Speed Controller Witches

– Temperature & RPM meter with temperature sensor and Selec Meters

– Batch time monitor meter (selec/Multispan)

– Reverse Switch/ Pot

– Cable & wiring: Polycab/FINOLEX

– MCB inside Panel: Siemens main incomer – L&T

– Machine Design and Developed as Per Fssai Norms

“Machine Capacity 12 to 25 KG, per charge/batch which takes time for 35 to 40 minutes only. Revolution of drum 2 TO 14 R.P.M. Electric power Consumption 03 Units for per charge. One man can operate two machines at a time. The machine requires floor space 4ft. X 4.5ft. only. Even Ladies can operate these machine as they are simple in construction and easy to operate. The drum rotates itself machine do not need any type of foundation.”